Accelerate Your Product Development with Elastic Contacts

Our team at Lux Veritatis offers expert consultation and support for R&D teams exploring the potential of elastic contact technology. Elastic contacts are revolutionizing the design and performance of electrical equipment, allowing for unprecedented efficiency, reliability, and scalability in various applications.

How We Can Help: Send us the design specifications of your contact assembly that requires enhancement, along with the desired performance parameters such as current, voltage, and whether the application is for AC or DC circuits. We’ll assess the compatibility and potential advantages of integrating elastic contacts into your design.

Examples of Applications:

- Vacuum Interrupters

- Contactors for High Voltage DC

- Gas-Insulated Switchgear

- DC Contactors for Electric Vehicles

- Switches for Ultra-High Pulse Currents in the Megaampere Range

With elastic contacts, these applications benefit from reduced contact resistance, minimized heating, and exceptional durability.

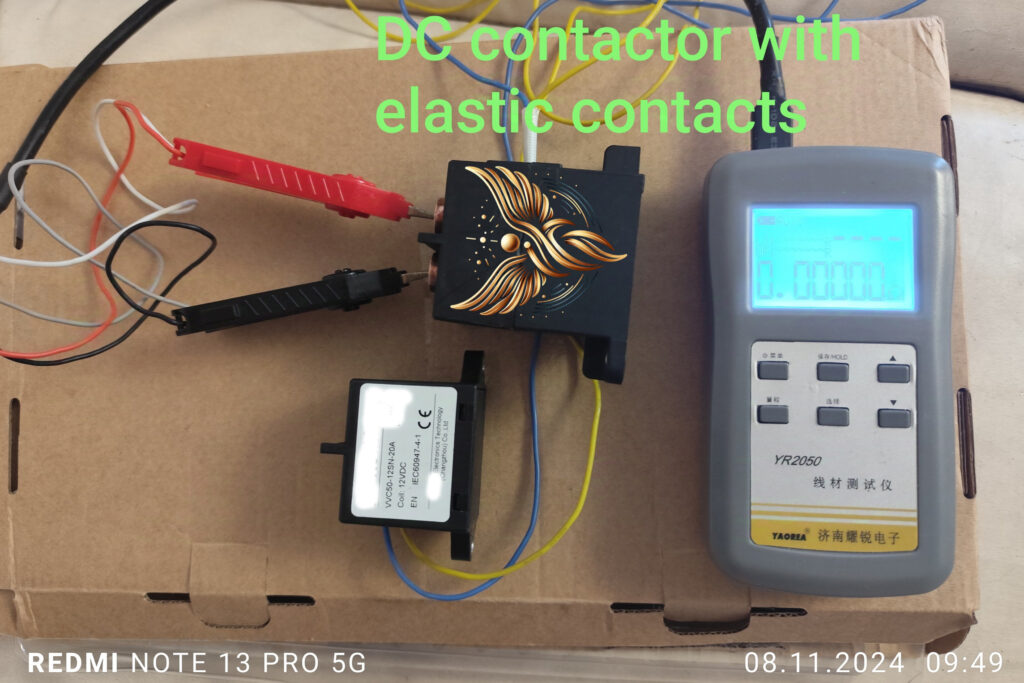

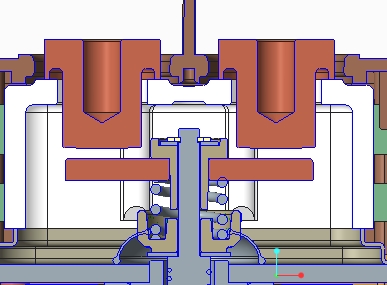

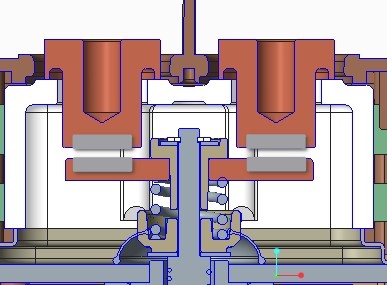

Case Study on Automotive DC Contactors: In the images shown, we successfully retrofitted traditional copper contacts in a high-voltage DC contactor for an electric vehicle with elastic contacts. This development, from initial design to finished prototype, took only one week. The result was a significant improvement in performance, showcasing the advantages of elastic contact technology in high-stress environments.

A leading automotive developer approached us with a recurring issue: overheating contacts in widely used automotive DC contactors. Despite various attempts to mitigate the problem, traditional solutions were proving ineffective in high-current applications.

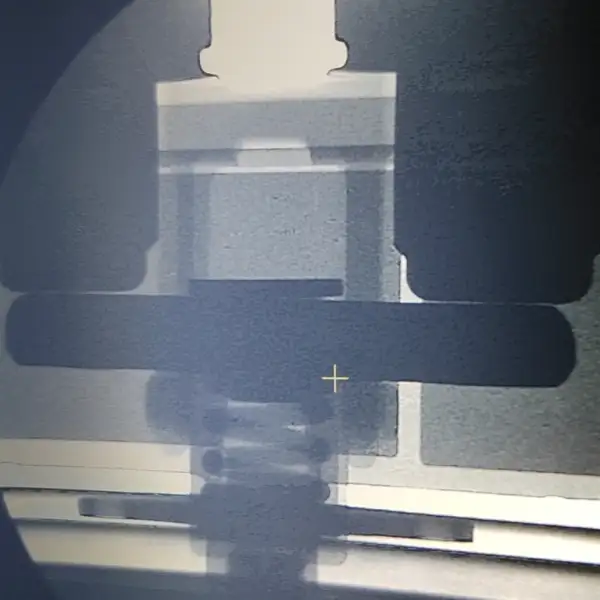

X-ray analysis revealed a critical flaw in the contact design. The contacts engage at only a single point on each electrode. This limited contact area results in excessive heat buildup and vibration, leading to instability and reduced lifespan.

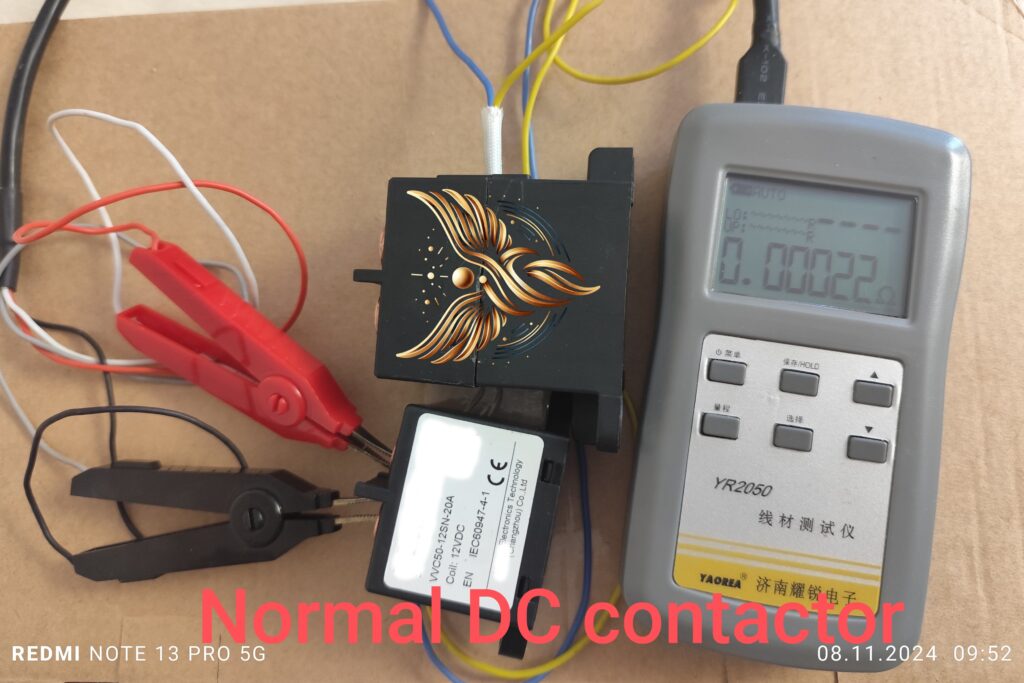

In conventional DC contactors, solid contacts rely on high pressure and specific alignment to maintain connectivity. However, the point contact nature leads to localized heating and mechanical wear, both significant contributors to performance degradation.

Our team proposed a breakthrough solution — the integration of elastic contacts. These contacts distribute current evenly across the entire contact surface, eliminating the issues associated with point contact and reducing heat generation by orders of magnitude.

The finished DC contactor with elastic contacts demonstrated stable performance under high currents with minimal heat buildup and no vibration issues. Development from initial diagnosis to a fully functional prototype took only one week, underscoring the rapid adaptability of elastic contact technology in critical applications.